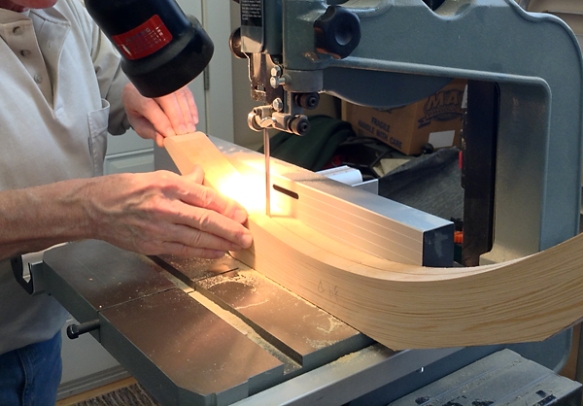

Once the planks were glued up, they were cut to shape using the full-size patterns. We used three different methods to attach the planks. The garboards were screwed into the bottom panel using temporary screws, pre-drilled and driven in at an angle. With the middle planks we were able to use plywood clamps and wedges. This method is excellent for glued plywood lapstrake planking but unfortunately was not possible for fastenening the garboards due to their width. Nor was this method suitable for the sheerstrakes because the sheerclamp was in the way. To attach them, we used temporary screws along the sheer clamp. At the landing, a batten was fastened with screws and spacer blocks to the frames, stem and transom. Wedges were then slipped in between the batten and the plank to apply pressure.

T

T